Sustainable Design and Innovative Management

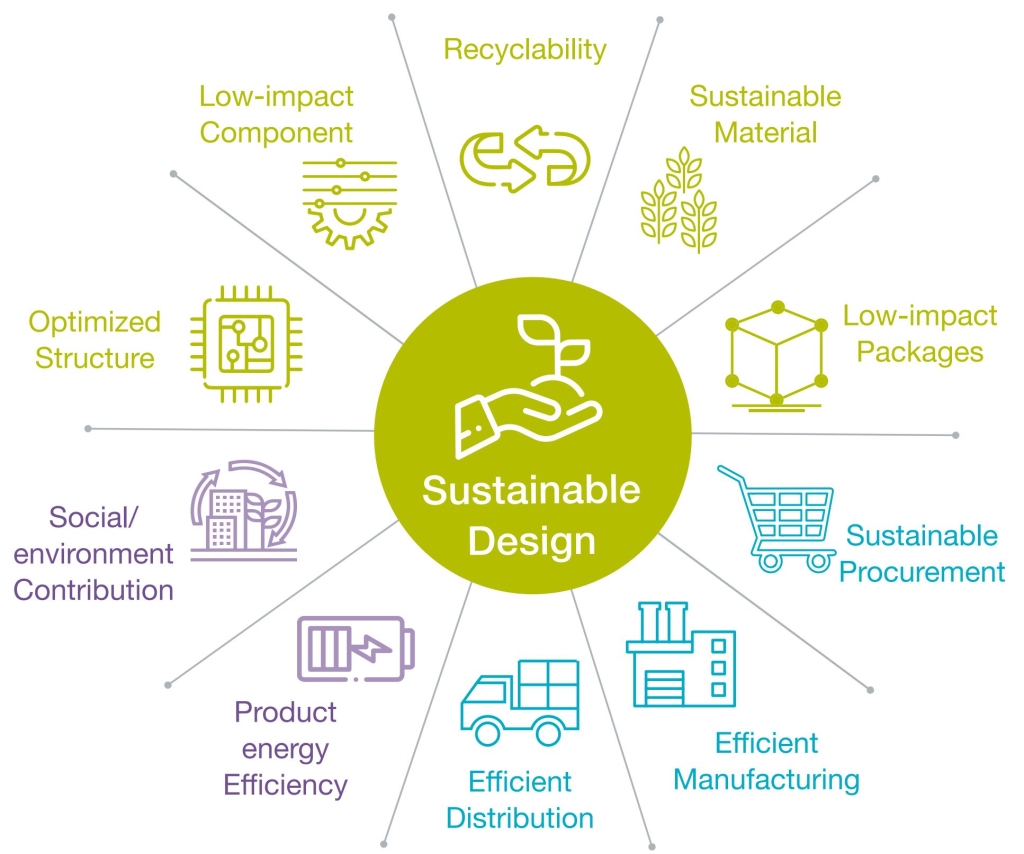

Innovative management is one of the crucial driving factors for the Company to continue maintaining its advantages in the future. Merry has long been focusing on investments in R&D capacity and grasping new industrial opportunities. Regarding product innovation, procedure innovation, and open innovation, it combined the trends of sustainable designs and low-carbon transformation and focused on principles combining concepts of the product lifecycle and circular economy. Starting from the design stage of products, it consolidated micro-function, automated equipment, smart electroacoustic platform, battery integration, and other objectives to minimize the impacts of products on the environment and create sustainable values.

Merry combined the spirit of innovative management with ten aspects of sustainable designs to assist customers in producing advanced and effective products. It continues to improve the modulization of production and manufacturing and product design capacity, save manufacturing materials, use renewable materials and environmental-friendly packaging design, adopt stages to reduce electricity consumption to realize its green manufacturing commitments starting from the interior of the Company and realize the sustainable value of environment and society.

| |

Type of Improvement |

2022 Achievement |

| Innovation achievements of products and procedures |

Optimized structure |

For the light new products, through the optimization of the structural design, the partial thickness of plastic parts was reduced, and the weight reduction accounts for approximately 15% of the overall materials and 4% of the total weight of earphones; delicate adjustments and screw locking positioning were made in response to the structure to for optimization, and the use of overall PCB plat materials reduced by 33%.

|

| Circular Economy |

Introduced the use of renewable materials facilitated the number of customers’ new products adopting post-consumer recycled (PCR) for the plastic covers; meanwhile, the ratio of PCR to materials also increased from 20% at the beginning of the target setting to 30%, continuing to expand the effects of Merry in terms of green products.

|

| Low-Impact Packaging |

Continue to promote environmental-friendly packaging design and carry out designs and packaging material and printing ink reduction based on the philosophy of environmental protection and the reduction of resource waste, reduce the use of plastic materials by adopting recyclable or degradable packaging materials, and print the instruction on the inner side of the cover. After the overall optimization, the volume of paper boxes was reduced by 50%, which significantly reduced impacts on and damage to the environment.

|

| Energy Efficient |

Improve the conversion efficiency of charging/discharging of battery products and reduce the energy consumption during charging/discharging; the charging/discharging conversion rate of energy storage products has reached 87%. As compared to products in 2020, the new generation mobile energy storage system may reduce approximately 8.4kWh of power for charging 120 times a year.

|

| Efficient Delivery |

Fulfilling product protection, convenience, sales, and other functional conditions, the size of the overall packaging box was reduced, which improved the use efficacy of packaging and warehouse space and improved the number of products that may be loaded onto a single pallet. Taking entertainment earphone products as an example, the number of products that may be loaded increased by 114%, which significantly improved the loading efficiency of pallets and reduced the number of transportation containers and requirements for warehouse storage. With the same shipping quantity, approximately 63%of carbon emissions may be reduced for product delivery.

|

| Efficient Manufacturing |

Integrate OT and IT, the two major technologies, for production line intelligence upgrades.

1. The modularized designs of automated machines reduced the workload of production line changeover design by 70% and reduced the cost of changeover by 50%

2. The modularized designs of carriers reduced the workload of jig alteration by 60% and reduced the cost of jig by 60%

3. The production line set-up time has been reduced from 8-12 weeks to 5 weeks, and the target is to reduce it to 3 weeks by 2025

|

| Open innovation achievements |

Social contribution |

Engage in medical innovative products in 2022 - passive AI smart fetus sensor technologies

Successfully developed the AI fetus sensor, which is developed by using the highly sensitive MEMS microphone and clinically verified in cooperation with medical institutions. The sensor is able to improve the deficiency of existing equipment to help pregnant women monitor fetuses’ conditions.

Deficiency of market equipment: Fetus sensors currently used by obstetrics and gynecology departments are active inspection that makes use of the theory of ultrasonic to detect fetal heart rates (FHR).

FHR monitoring equipment used clinically is large and pricey and may not be used for real-time monitoring at home. If fetuses have any particular circumstances, pregnant women are unable to instantly acknowledge and respond.

Advantage of innovative product: For the product, the Company will develop a passive fetus monitoring system that does not require ultrasonic monitoring technologies and simplify monitoring devices and operations. Users may operate the system themselves together with mobile apps and networks to provide information to doctors for subsequent analysis or diagnosis via home monitoring.

|

Efficient Manufacturing

Integrate OT and IT, the two major technologies, for production line intelligence upgrades and carry out comprehensive improvements in terms of efficiency, accuracy rate, and product quality.

Information upgrade

With the arrival of Industry 4.0, in combination with 5G applications and Big Data collection, the Company converted data to “visualized data” via plant equipment to collect comprehensive production information (including supplies, workstations, equipment, and test data), together with automatic background calculation, and provide digital decisions rapidly.

Upgrades of operating technologies

Optimize the SPK procedures, SMT and automated module assembly capacity, introduce SPK magnetic circuit automatic assembly machine, unmanned robotic arms, automated welders, automated guided vehicles, and other automated solutions to reduce the workload of changeover designs by 70% and reduce the cost of changeover by 50% and significantly improve the product assembly capacity in order to achieve the optimal production efficiency alongside the increase in equipment utilization rate.

Production line of high flexibility

The life cycle of consumer products has shortened, and products are produced in small quantities but diverse models with a large demand during the initial marketing period. The output in the first three months may account for 50% of the total requirements of orders; therefore, production lines of high flexibility shall be created, combined with the introduction of automated equipment, to solve the costs of mass changeover and labor requirements at the initial period of mass production.

IP rights management

To protect R&D outcomes and enhance corporate competitiveness, based on the IP management policy, we set up management targets; acquire, protect, maintain, and use intellectual property; and adopt measures to avoid infringement and protect rights.To constantly strengthen the awareness of and capacity in intellectual property, in 2019, we passed the category A certification of the Taiwan Intellectual Property Management System (TIPS) version 2016. In 2022, we also passed the re-certification. In 2018, Merry Shenzhen passed GB/T 29490-2013 enterprise intellectual property management certification and continued to pass the periodic re-certification each year.

Management policy

- • Maintain the freedom of operations

- • Strengthen the awareness of IP rights protection among employees

- • Enhance the protection of IP outcomes and create high-value-added IP portfolios

Based on the abovementioned specifications, the legal and patent department periodically presents the assessment reports of management processes that require adjustment to top management for approval.The Legal Affairs and Patent Department also updates the patent map for the trend of new products and technologies for the reference of the R&D unit.The legal and patent department and the relevant units of subsidiaries compile reports on legal requirements and industry information. Additionally, they also promptly inform R&D units of the relevant risks in patent application during product development.If the IP rights investigation report shows that there is any legal risk, the proposing unit and the legal and patent department will immediately plan, establish, and implement the risk countermeasures and risk avoidance plans.The implementation items of the abovementioned IP right management, as well as the next-year implementation plan, are periodically reported to the Board each year and disclosed on the Company’s website.Additionally, in terms of patent approval, as shown in the figure below, we applied for 91 patents and were awarded 68 patents in 2022, and there are 314 validly existing patents at present.